Introduction to Closed Suction Catheters Closed suction catheters are medical devices used to clear the airways of patie...

View MoreIntroduction to Silicone Resuscitators Silicone resuscitators, also known as manual resuscitation bags or Ambu bags, are...

View MoreUnderstanding Gas Leakage in Anesthesia Delivery Anesthesia masks are essential components in inhalation anesthesia syst...

View MoreGeneral characteristics of silicone reservoirs A silicone reservoir is a container or flexible storage component manufac...

View MoreIntroduction to Cervical Ripening and the Role of Cervical Ripening Balloon Cervical ripening is a critical part of the ...

View MoreWhat are the characteristics and advantages of PVC resuscitator?

PVC resuscitators, also known as manual resuscitation bags or bag-valve masks (BVMs), are widely used in emergency medicine, anesthesia, and intensive care settings. They are designed to provide positive pressure ventilation to patients who are not breathing adequately or who have experienced respiratory arrest. The resuscitator typically consists of a self-inflating bag, a one-way valve, and a mask or a connection port for an endotracheal tube. PVC resuscitators are a common choice due to the properties of PVC material, which can support flexible design and consistent performance. In clinical environments, they are used for resuscitation during anesthesia induction, cardiopulmonary resuscitation, and patient transport.

PVC, or polyvinyl chloride, is a type of plastic commonly used in medical devices. In resuscitators, PVC provides flexibility and elasticity that allow the bag to be compressed and return to its original shape. The material also supports transparency, which enables healthcare providers to observe the bag’s inflation and monitor any potential condensation or blockages. PVC can be manufactured with controlled softness to achieve a balance between ease of squeezing and sufficient recoil, which is important for delivering consistent ventilation volumes. Additionally, PVC is compatible with a range of production processes, including injection molding and extrusion, which supports consistent manufacturing in controlled environments such as clean workshops.

PVC resuscitators are designed to support efficient manual ventilation through a combination of components and ergonomic considerations. The self-inflating bag is shaped to fit comfortably in the hand, enabling the operator to deliver repeated compressions without excessive fatigue. The one-way valve system ensures that air flows into the patient during compression and prevents backflow during release, which helps maintain the safety and effectiveness of ventilation. In many resuscitators, the connection port can accommodate a mask or be attached to an endotracheal tube for more controlled airway management. These design features support the device’s role in emergency and perioperative care where quick and reliable ventilation is required.

PVC resuscitators are commonly used in various clinical scenarios, including emergency response, anesthesia induction, and patient transfer. During anesthesia, they can be used to support ventilation while the patient is being intubated or while breathing is being monitored. In emergency settings, such as cardiac arrest or respiratory failure, the resuscitator provides immediate ventilation support until advanced airway management can be established. During patient transport within the hospital, the device offers a portable solution for maintaining ventilation. The versatility of PVC resuscitators makes them a standard tool in many healthcare settings where rapid response to respiratory emergencies is needed.

PVC resuscitators are often used in combination with other airway devices and accessories. For example, a laryngeal mask airway or an endotracheal tube can be connected to the resuscitator to support a secure airway. In clinical practice, it is important that these connections are compatible and secure to prevent leaks and ensure effective ventilation. The compatibility extends to oxygen tubing and filters, which can be attached to the resuscitator to deliver oxygen-enriched air and reduce contamination risk. The ability to integrate with other respiratory consumables is one reason why PVC resuscitators are widely used in anesthesia and critical care.

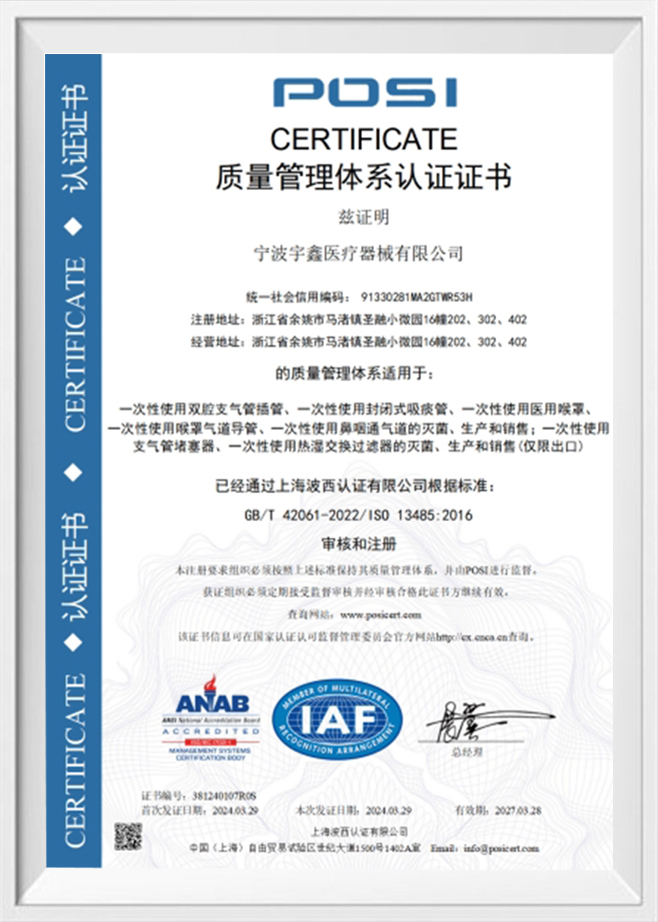

Producing PVC resuscitators requires controlled manufacturing conditions and quality control to ensure safety and performance. High-tech medical enterprises, such as Ningbo Yuxin Medical Equipment Co., Ltd., emphasize clean workshop environments and advanced production equipment to maintain product consistency. The company’s 100,000-level clean workshop and 10,000-level laboratory support controlled production and testing processes. Equipment such as plastic injection molding machines and plastic extruders are commonly used to produce PVC components with consistent thickness, shape, and mechanical properties. These manufacturing capabilities support the reliable production of respiratory consumables, including PVC resuscitators and other airway devices.

Safety and infection control are key considerations in the use of PVC resuscitators. In clinical practice, resuscitators may be used in high-risk situations where patients are vulnerable to infection. To reduce the risk of cross-contamination, disposable PVC resuscitators are often preferred, especially in emergency and critical care settings. Proper storage, handling, and disposal are important to maintain hygiene and prevent contamination. Additionally, the use of filters and accessories can further reduce the risk of pathogen transmission by trapping particles and microorganisms before they enter the respiratory circuit. In settings where equipment is reused, thorough cleaning and sterilization protocols are essential.

The performance of a PVC resuscitator is influenced by factors such as bag elasticity, valve function, and mask fit. The bag must provide reliable recoil to allow for consistent ventilation cycles. The valve should function smoothly to prevent air leakage and ensure one-way flow. The mask or airway connection must fit securely to avoid air loss and to maintain patient comfort. In pediatric or neonatal settings, smaller resuscitator sizes may be used to match the patient’s lung capacity and reduce the risk of over-inflation. In adult settings, larger sizes are used to deliver adequate tidal volume. The ability to select appropriate sizes and maintain good mask seal contributes to the effectiveness of manual ventilation.

| Characteristic | What It Means | Clinical Impact |

|---|---|---|

| Material Flexibility | PVC can be produced with controlled softness and elasticity | Supports consistent bag compression and recoil |

| Transparency | Clear material allows visual inspection of the bag | Helps monitor inflation and detect condensation or blockages |

| Compatibility | Designed to connect with masks, tubes, and oxygen supply | Supports integration with other respiratory devices |

| Portability | Self-inflating bag design requires no external power | Useful in emergency response and patient transport |

In some clinical environments, customized resuscitator designs may be required to meet specific needs. OEM manufacturers, such as Ningbo Yuxin Medical Equipment Co., Ltd., can offer customized silicone and plastic accessories to support different medical applications. Customization may include variations in bag size, valve configuration, connection ports, and packaging. The company’s advanced production equipment and clean workshop environment support the development of customized respiratory products. This flexibility can help healthcare providers obtain resuscitators that fit specific protocols and patient populations.

PVC resuscitators are often used alongside airway management tools such as laryngeal masks and endotracheal tubes. In anesthesia, they provide ventilation support during induction and recovery. In emergency care, they are used to provide immediate ventilation before advanced airway devices are placed. Proper integration with airway tools is essential to ensure a secure airway and effective ventilation. The ability to connect the resuscitator to different airway devices makes it a versatile tool in clinical practice. The coordinated use of resuscitators with other respiratory consumables helps support patient safety and treatment outcomes.

Operational considerations include storage, training, and ease of use. PVC resuscitators should be stored in a clean, dry environment to maintain material integrity. Healthcare providers should receive training in proper bag compression techniques, mask sealing, and monitoring of ventilation parameters. The design of the resuscitator should support easy handling and quick deployment in emergencies. In busy clinical environments, the ability to quickly access and use the resuscitator can impact patient outcomes. The reliability of the device, combined with proper training and operational readiness, supports its role in emergency and perioperative care.

FAQ

Q: What are the common materials used in resuscitators, and how do they affect performance?

A: Resuscitators are often made from materials such as PVC, silicone, and other medical-grade plastics. PVC is commonly used for its flexibility and transparency, which allows clinicians to monitor bag inflation and detect condensation or blockages. Silicone can provide greater durability and a softer feel, which may help with repeated use and patient comfort. Material choice affects factors like elasticity, recoil, compatibility with sterilization methods, and overall handling during emergency ventilation.

Q: How do resuscitators integrate with other airway devices during emergency or anesthesia procedures?

A: Resuscitators are designed to connect with masks or airway devices such as laryngeal masks and endotracheal tubes. During anesthesia induction or emergency ventilation, a resuscitator can be used to deliver positive pressure ventilation while the airway is being secured. It is important that the connection ports and fittings are compatible and secure to prevent air leakage and ensure effective ventilation. In clinical settings, resuscitators may also be connected to oxygen sources and filters to support patient safety and oxygen delivery.

Q: What factors influence the choice between disposable and reusable resuscitators?

A: The choice depends on infection control requirements, cost considerations, and clinical context. Disposable resuscitators are often preferred in emergency and critical care environments where rapid deployment and reduced contamination risk are priorities. Reusable resuscitators may be selected in controlled environments with strict cleaning and sterilization protocols. The decision also considers the availability of clean workshop production and quality control measures that ensure consistency and safety in device performance.

Q: How does the design of the bag and valve system affect ventilation efficiency?

A: The design of the bag influences how easily it can be compressed and how well it recoils, which affects the consistency of delivered tidal volume. The valve system ensures one-way flow, preventing backflow during release and helping maintain positive pressure ventilation. A well-designed valve reduces air leakage and supports efficient airflow. Clinicians also need to monitor for resistance and adjust compression techniques accordingly, especially during prolonged ventilation or when using the device on patients with varying lung compliance.

Q: What role does manufacturing environment play in ensuring the quality of resuscitators?

A: The manufacturing environment is crucial for maintaining product safety and consistency. A controlled clean workshop and laboratory testing help ensure that resuscitators are produced under conditions that minimize contamination risk. Companies like Ningbo Yuxin Medical Equipment Co., Ltd., which operate a 100,000-level clean workshop and a 10,000-level laboratory, can maintain strict quality control over materials, production processes, and finished products. Advanced equipment such as plastic injection molding machines and plastic extruders supports stable manufacturing and reliable performance.

Q: How should resuscitators be maintained and stored to ensure readiness in emergency situations?

A: Resuscitators should be stored in a clean, dry environment away from direct sunlight and extreme temperatures. Packaging should remain intact to prevent contamination. Regular inspection is necessary to check for material degradation, valve integrity, and any signs of damage. Training for clinical staff on proper handling and storage helps ensure that resuscitators are ready for immediate use during emergencies. In facilities with high turnover, maintaining an inventory of disposable units can help ensure availability.

Q: What are the considerations when selecting resuscitator size for different patient groups?

A: Patient size and lung capacity are important factors when selecting resuscitator size. Pediatric and neonatal patients require smaller bags and masks to avoid delivering excessive tidal volume, while adult patients require larger sizes to ensure adequate ventilation. The choice also depends on the patient’s condition and whether the resuscitator will be used with a mask or connected to an endotracheal tube. Clinicians must select the appropriate size to match the patient’s needs and avoid complications related to over-inflation or insufficient ventilation.

Q: How do resuscitators support oxygen delivery in clinical settings?

A: Resuscitators can be connected to an oxygen source to deliver oxygen-enriched air during ventilation. This is particularly important in emergency situations and during anesthesia where oxygenation must be maintained. The connection is typically made through an oxygen inlet port, and clinicians may use additional accessories such as filters to ensure safety and reduce contamination. Proper connection and monitoring of oxygen flow help ensure that the patient receives the required oxygen concentration during manual ventilation.